About us

Knittel Glass, a StatLab company, was founded in 1987 by the entrepreneurial Mister Waldemar Knittel in Braunschweig, Germany. Today, Knittel is recognized as a leader in high-quality German glass products for anatomic pathology evaluations, as well as an engineering consulting service provider to the broader glass manufacturing industry

A strategic business combination with StatLab at the end of 2023 positioned the business to undertake planned investments in expanding its manufacturing capacity to better service its customers in the U.S. and Europe.

StatLab Medical Products has been dedicated to helping anatomic pathology laboratories provide the best possible patient care since 1976. We offer an extensive portfolio of self-manufactured consumables and labeling and tracking equipment from five manufacturing sites in the United States, United Kingdom, and Germany. Our global operational footprint powered by over 500 mission-driven colleagues delivers a dependable and resilient supply chain of high-quality products and solutions, and a customer-centric approach inspires us to deliver reliability, innovation, and quality in every interaction.

Our range of products

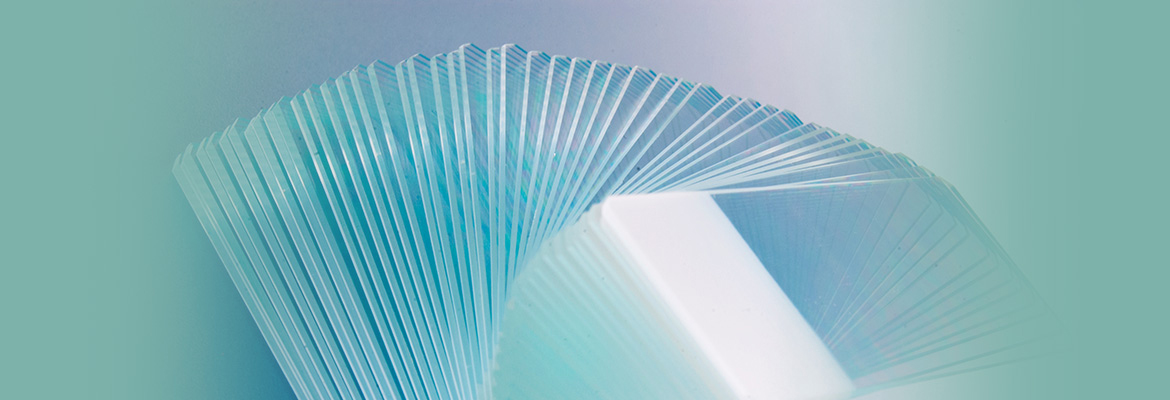

Today, the production of Waldemar Knittel Glasbearbeitungs GmbH comprises the full range of slides and coverglass, from our cheapest, the cut edge slides to our twin frost slides, to our ground edge slides with different edges (e.g. 45°, 90°, bevelled), and various surface treatments (e.g. twin frosted and single frosted). Additionally, we offer concavity slides and counting chambers for various applications, as well as printed slides with and without selective coatings.

Our unique, licenced StarFrost® product range with our registered trademark, the StarFrost® adhesive slides and our application orientated or customised diagnostic slides are available in various colours.

Our high-quality coverglass is available as squares, rectangles or as circles in different dimensions and thicknesses and can be used manually or within automatic coverslippers. Further, we offer our Starbox®, especially designed for medical practice as a very lightweight archive box made of a non-polluting foam, as well as alcohol resistant Markers.

Our sensitivity to quality

For many years we have been an ISO 9001 and 13485 certified company.

As a CE/IVD manufacturer the compliance of our processes and systems are our top priority. This guarantees that we are a reliable partner for our customers.

The combination of high quality raw materials, production efficiency and process quality is our strength. We always try to exceed our customers requirements and expectations. To us quality not only means compliance regarding the agreed specifications and documentation but also the quality of our partnership.

Most of our products are manufactured on automated production lines with integrated quality controls. The slides and cover glasses are conform to the relevant international ISO standards but can meet the customer’s special requirements , e.g. customized slide layouts and packaging, at the same time.

Our company offers CE-marked IVD slides and cover glasses complying with all applicable requirements of EU Regulation 2017/746 on IVD medical devices (IVDR).

Our Mission

Our Mission is simple. We empower laboratories to provide the best patient care possible. This drives everything we do throughout our organization.

Here at Knittel, we know that our mission and success will only be accomplished by innovative collaboration between all of our teams.

Synergies from the engineering department in Bielefeld inform the production of high-efficiency lines, and we’re constantly seeking ways to improve product performance and partner well with our distributors. Now as a part of the broader StatLab organization, we are equipped with resources to continue to advance and expand local operations.